Striking the right balance between inventory holding and movement costs while offering competitive service contracts, has long been one of the biggest challenges faced by Original Equipment Manufacturers (OEM) or After Sales Service Providers (ASSP). Since the OEM’s spare parts planning is predominantly a procure-to-stock process, planning is almost entirely based on forecast. This explains why the spare part demand forecast is an extremely critical aspect of the OEM’s spare parts planning process.

Demand forecasting is a challenging science. The demand for spare parts is usually intermittent, erratic and slow moving. An abundance of high-quality data is the cornerstone of demand analysis or forecasting. More often than not, the required data is not available or reliable forcing OEMs to do a basic extrapolation of historic demand. Often the traditional time series forecasting method results in over-ordering that leads to the accumulation of slow-moving products throughout the supply chain and the inability to optimise. The reality is that OEMs seeking to deliver superior service at competitive rates requires a level of reliability in forecasting which cannot be met by time series forecasting methods alone.

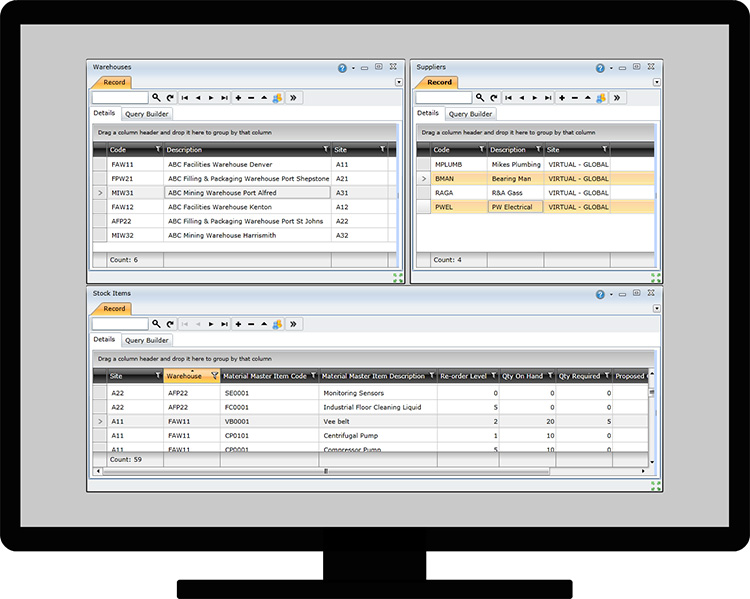

A more advanced forecasting approach does not rely on historic demand data alone but includes data about the installed base. The installed base is usually defined as the whole set of equipment an OEM has sold and are still in use.

Unfortunately, the journey to more mature installed base information management is riddled with obstacles. Equipment is usually complex, consisting of several hierarchies, like subassemblies and parts. Added to that different combinations of subassemblies that are configured together and changed over time which requires disciplined configuration management. The OEM sets off with the pure objective to build standard equipment, but any form of customisation makes each piece of equipment specific. OEMs do not have information on how and where the equipment owner uses the equipment unless the owner has a service contract. In many cases, the owner moves the equipment from one place to another without informing the OEM.

But like all good journeys, one does not start without a plan. To determine the installed base information required to assist demand forecasting, it is important to understand the lifecycle of the equipment. Most equipment exhibits a demand lifecycle pattern with an initial growth, maturity and a final decline phase. With this understanding, the management of installed base information to support spare part demand forecasting can be crafted and implemented.

The demand for spare parts will follow the demand for the equipment, but with a delay. Solomon et al. (2000) refer to this as the “Lifecycle Mismatch”. There might be some initial spare part demand accompanying the commissioning phase of the equipment, but the bulk of spare part demand due to deterioration and failure will happen through the life cycle of the equipment, but at an increase as the installed base age.

Based on the availability of accurate and complete installed based information, the correct forecasting method can be selected per equipment. Equipment that is in the mature phase can make use of a sophisticated forecasting method that includes maintenance plans, usage patterns and any form of customisation.

The benefits of building spare part demand forecasting models on installed base information are primarily the improvement on the accuracy and timeliness of the forecast, in comparison with forecasts only based on historic demand. The question remains what the investment is to implement installed base information management strategy, and what value will result from it. The complexity of the effort to implement and maintain installed base information increase with the size of the installed base and the magnitude of the characteristics of spare parts demand; but so too does the benefits of building a more sophisticated forecasting model. The logical approach would be to start by focusing on slow moving expensive spare parts to test the concept and prove the value, and then to progress from there. Also, prioritise the equipment systems where installed base information is most complete in relation to the phase that the installed base is in.

I’m convinced that a good, accurate installed base management strategy has many far reaching benefits to the OEM. One of which is a much improved and accurate spare part demand forecast.